Text Language Definition

procedure TNAxis.BeginMoveTo(XDelta:double; YDelta:double....);

Description

Begin Move To initiates an absolute coordinated move to the specified position parameters but does not wait for the move to finish before continuing. The method requires as many parameters as the dimension of the axis group. A single axis has one parameter. A group with 3 axes requires 3 parameters. The motion is performed with a trapezoidal velocity profile based on parameters set with the Set Accel , Set Decel , and Set Speed _BLOCKs. These parameters apply to the vector path motion of the coordinated group rather than to any particular axis. Begin Move To is a nonblocking command. Execution continues immediately allowing other actions to be performed while the motion is occurring. It is often necessary at some point to wait for the motion to finish which is accomplished with the Move Is Finished command. If there is nothing to do during the motion it is simplest to use the Move To blocking form of the command. Begin Move To can be used on an axis that is already in motion. The target will be changed to the new destination. The Stop, Begin Stop, and Abort commands will end the motion before it reaches the target position.

Escapes

Begin Move To will produce an Axis Is Busy Escape Code if a coordinated group is already in motion.

A single axis can be directed to a new destination while in motion as long as the destination is still ahead of the current position in the current direction of travel and obtainable with the current decel setting. If not a Motion Overrun Escape Code will occur.

If the destination of the move is beyond the positive and negative software limits, the Begin Move To block will produce a Position Limit Escape Code.

Examples

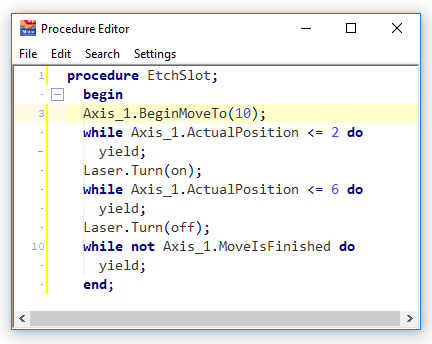

This procedure initiates a move and then produces a pulse over a specific distance:

The laser will be turned on at the first sample after the positions has been achieved. This would typically be maximum of 1 millisecond if the controller sample rate is the default 1000 Hz but could be reduced to as little as 125 microseconds if the sample rate is set to 8000 Hz. For higher resolution accuracy, down to individual counts, hardware compare features are available in specific controller families.

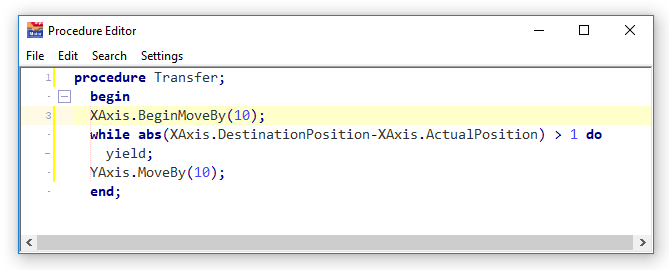

This block list saves time during a part transfer by initiating the orthogonal axis move early creating a corner rounding effect:

Related Topics

Begin Move By

Move To

Set Speed

Set Accel

Set Decel

Move Is Finished